Ukuhlolwa kokusebenza kwe-1.Rolling

Inhloso: Ukuhlola ukusebenza kwesondo le-caster ngemva kokulayisha;

Imishini yokuhlola: i-caster single wheel rolling, umshini wokuhlola ukusebenza kokuqondisa;

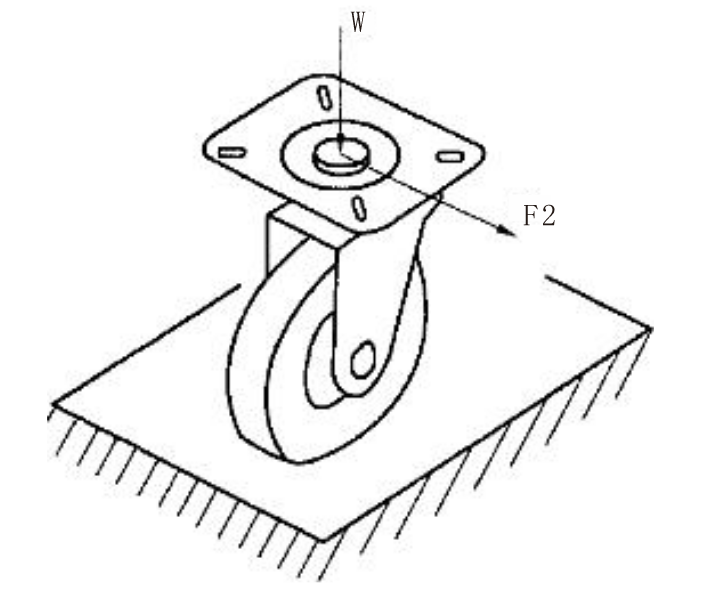

Izindlela Zokuhlola: Njengoba kubonisiwe kuMfanekiso 1, faka i-caster noma isondo emshinini wokuhlola, sebenzisa umthwalo olinganiselwe u-W ku-caster eduze nendawo yokumisa ipayipi bese usebenzisa amandla ku-ekseli yesondo endaweni evundlile. Linganisa amandla amancane F1 adingekayo ukuze uphendukise icaster noma isondo

Ukumelana nokuginqika kwesondo elilodwa kubalwa ngokwezibalo (1).

pl=F1/W…… (1)

Lapho μ1 i-coefficient yokumelana nokugoqa;

Ukumelana nokugoqa kwe-F1, iyunithi yi-Niu (N).

Umthwalo olinganiselwe, ngo-Nm (N).

Okungukuthi: i-propulsion F1 = umthwalo W × i-coefficient yokumelana μ1

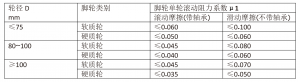

Ukusebenza kwesondo elilodwa le-caster kuzohambisana ne-GB/T14687-2011 ejwayelekile kazwelonke (Ithebula 1).

2.Ukuhlolwa kokusebenza kokuqondisa

Inhloso: Ukuhlola ukusebenza kokuqondisa kwabalingisi bendawo yonke ngemva kokulayisha;

Imishini yokuhlola: umshini wokuhlola ukusebenza kwe-caster rotation steering.

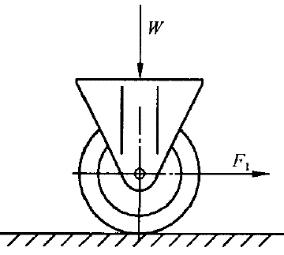

Indlela Yokuhlola: Njengoba kuboniswe ku-Fig. 2, faka i-caster noma isondo emshinini wokuhlola, sebenzisa umthwalo olinganiselwe u-W ku-caster eduze nendawo yokuqondisa ipayipi, futhi usebenzise amandla endaweni evundlile ebheke phambili ukuya phambili kwesondo. Linganisa amandla amancane okuthi F2 ukuqondisa i-caster, i-F2 iwukumelana nokuqondisa kwe-caster. I-coefficient yokumelana nokuqondisa ibalwa ngokuvumelana ne-equation (1).

μ2=F2/W …… (1)

lapho u-μ2 kuyi-coefficient yokumelana nokuqondisa.

Ukumelana nokuqondisa kwe-F2, ku-Nm; W Umthwalo olinganiselwe, ngo-Nm.

Umthwalo olinganiselwe ku-Nm.

okungukuthi: amandla okuphusha F2=i-coefficient yokumelana nomthwalo we-wX μ2

Ukusebenza kokuqondisa kuzothobelana ne-GB/T14687-2011 ejwayelekile kazwelonke (Ithebula 2).

3. Incazelo yamanani okuhlola.

I-coefficient yokumelana yokuhlolwa kusuka ku-1, isuka ku-2 encane, ekhombisa ukuthi ukumelana okuncane, kulula ukuyisebenzisa, ukuguquguquka okungcono: ngokuphambene nalokho, inani elikhulu, ukumelana okukhulu, kunzima kakhulu ukusebenzisa.

4. Ubudlelwano phakathi kwe-caster wheel surface material, i-movable frame disc material, into yebhola kanye nokumelana.

I-1) Ukuqina kokuqina kwe-caster wheel surface (efana ne-PA, MC, PP, isondo lensimbi, njll.), i-coefficient yokumelana incane, kulula ukuyicindezela, kodwa kubi kakhulu umphumela wokuvikela umhlabathi kanye nomphumela oyisimungulu.

2) Uma ingaphezulu lesondo le-caster liyinto ethambile (njenge-TPU, i-TPR, i-BR, njll.), uma i-coefficient yokumelana inkulu, amandla okushayela adingekayo, kodwa umphumela ongcono wokuvikela umhlabathi kanye nomthelela othulile.

3) Lapho buphakama ubulukhuni bediski kabakaki wamasondo anyakazayo kanye nezinto zebhola, kuncipha i-coefficient yokumelana nesiteringi futhi kuba lula ukuphusha.

Isikhathi sokuthumela: Apr-24-2024