I. Isakhiwo sabalingisi

Isakhiwo se-casters singahluka ngokuya ngokusetshenziswa okuhlukene kanye nezidingo zokuklama, kodwa ngokuvamile kuhlanganisa izingxenye eziyinhloko ezilandelayo:

I-Wheel surface: Ingxenye eyinhloko ye-caster yi-surface yesondo, evame ukwakhiwa ngamandla aphezulu kanye nezinto ezingagqoki, njengerabha, i-polyurethane, inayiloni noma i-polypropylene.

Ama-Bearings: Ama-Bearings atholakala ngaphakathi komzimba wamasondo futhi asebenza ukunciphisa ukungqubuzana futhi anikeze ukujikeleza okushelelayo. Izinhlobo ezivamile zama-bearings zihlanganisa ama-ball bearings kanye nama-roller bearings, futhi ukukhethwa kwabo kuncike kumthwalo nezidingo zejubane.

Ubakaki: Ubakaki uxhuma umzimba wesondo nesisekelo sokukhweza futhi unikeze ukusekela ukulungisa nokujikeleza kwesondo. Ubakaki ngokuvamile wenziwe ngensimbi ukuze uthole amandla nokuzinza.

Isikulufu: Isikulufu siyinduku emaphakathi exhuma umzimba wesondo kubakaki, futhi sivumela isondo ukuthi lijikeleze i-asili. Impahla kanye nosayizi we-shaft kufanele kufane nomzimba wesondo kanye nabakaki ukuze kuqinisekiswe ukuzinza nokuthembeka kwesondo.

I-Wave plate: i-wave plate idlala indima ekulungiseni i-caster nesiteringi, iwukhiye wokuzungezisa isondo lomhlaba wonke, i-wave plate enhle ijwayele ukuzungeza kalula, futhi ukusetshenziswa kwangempela kwesondo kuzosindisa umsebenzi. .

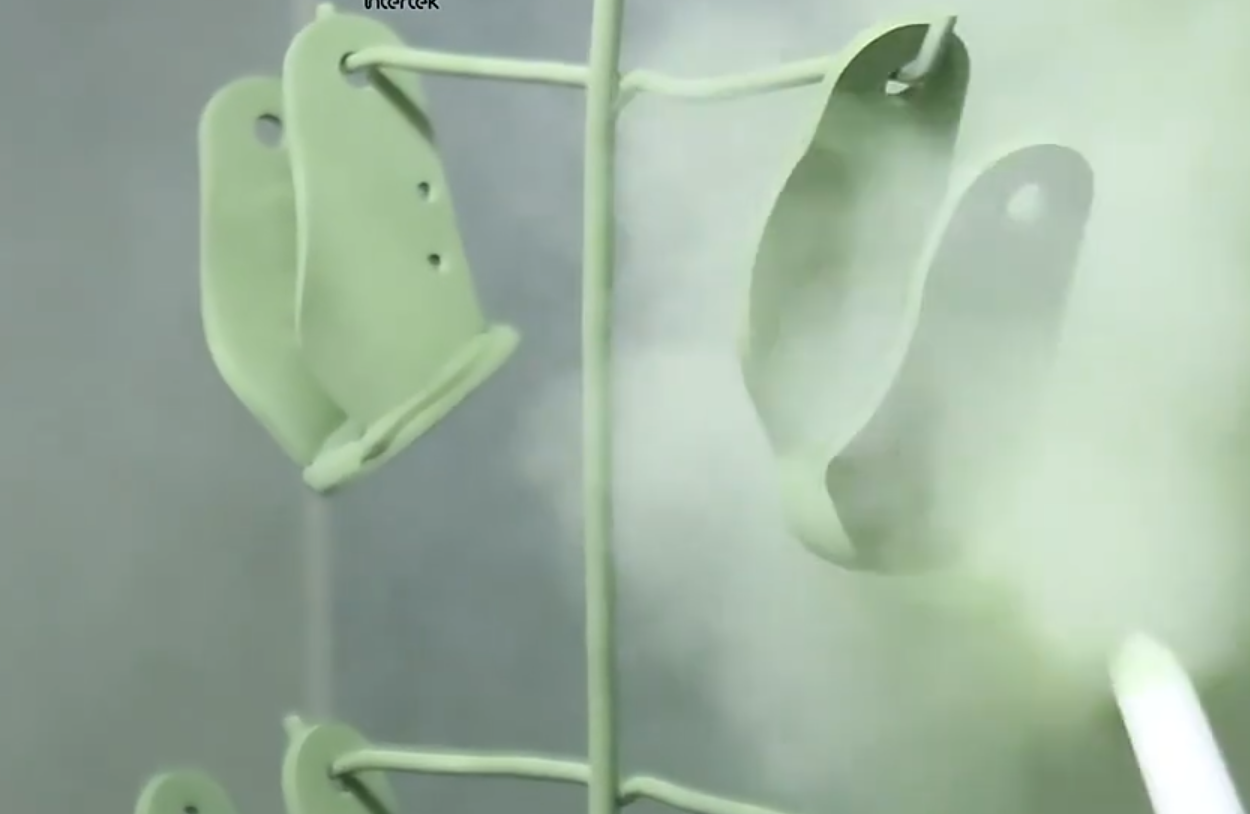

Okwesibili: inqubo yokufakwa kwama-industrial casters

Ukufakwa okulungile kuyisihluthulelo sokuqinisekisa ukusebenza okuvamile nokwelula impilo yesevisi yabakhangisi. Okulandelayo inqubo yokufaka ejwayelekile yama-casters ezimbonini:

Ukulungiselela: Ngaphambi kokufaka ama-casters, udinga ukufunda ngokucophelela imiyalelo yokufaka enikezwe umphakeli futhi ulungiselele amathuluzi adingekayo, njengama-wrenches, ama-screwdrivers nezando zenjoloba.

Ukuhlanza: Qinisekisa ukuthi indawo ekhwezwayo ihlanzekile futhi iyisicaba, ayinawo udoti kanye nezithiyo. Indawo ehlanzekile isiza ukuqinisekisa ukuthintana okuhle phakathi kwama-casters kanye nesisekelo sokukhweza.

I-Mounting Bracket: Vikela ubakaki emishinini ngokuya ngezidingo zokuklama okokusebenza kanye nemiyalelo yokunyuswa. Ngokuvamile zivikelekile ngokusebenzisa amabhawudi, amantongomane noma i-welding. Qinisekisa ukuthi ubakaki uqinile futhi unokwethenjelwa, futhi uhlole ukuthi ukulungele yini okokusebenza.

Faka umzimba wamasondo: Faka umzimba wamasondo ezimbotsheni zokuthwala zobakaki ukuze uqinisekise ukuthi ama-bearings afakwe kahle. Uma kunesidingo, sebenzisa i-mallet yerabha ukuze uthinte kancane umzimba wesondo ukuze ulenze lilingane ngokuqinile kubakaki.

Vikela i-shaft: Sebenzisa indlela efanele yokubopha (isb., izikhonkwane, amabhawudi, njll.) ukuze unamathisele i-shaft kubakaki. Qinisekisa ukuthi i-shaft ivikelwe ngokuqinile kubakaki ukuvimbela umzimba wesondo ukuthi ungaxegi noma ungawi.

HLOLA NOKULUNGISA: Ngemuva kokuthi ukufakwa sekuqediwe, hlola ngokucophelela ukufakwa kwe-caster. Qinisekisa ukuthi umzimba wesondo uzungeza ngokushelelayo futhi akukho msindo noma umsindo ongajwayelekile. Uma kunesidingo, yenza izinguquko ezifanele kanye nokulinganisa.

Ukuhlola Nokwamukelwa: Ngemva kokuqedwa kokufakwa, yenza ukuhlola nokwamukela i-caster. Qinisekisa ukuthi ama-caster asebenza kahle kumishini futhi ahlangabezane nezidingo zokuklama.

Isikhathi sokuthumela: Aug-01-2023