If you’ve ever been involved in the construction or mechanical field, you’ve probably heard of footings. For those unfamiliar with the term, footings are an important tool used to secure a building or piece of equipment. They ensure that large structures remain stable in the elements, as well as ensuring that mechanical equipment doesn’t move or tilt during operation.

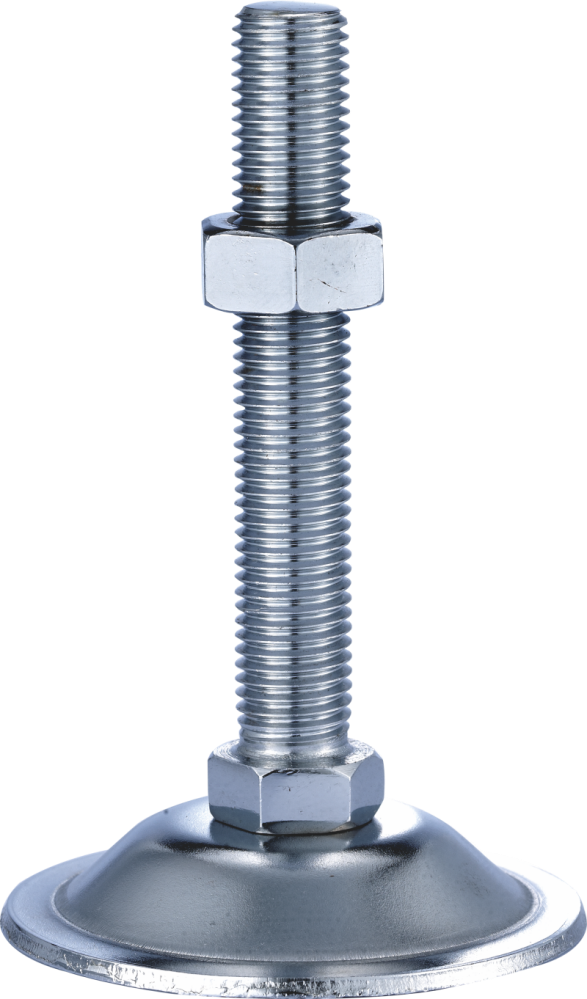

Feet are usually made of metal and have threads or studs that can be bolted or nutted to an object. They can withstand a great deal of weight and pressure and are a key factor in ensuring that equipment and structures are secure.

Different types of feet are used in different situations. Expansion bolts are a common type of footing in construction and engineering. They ensure a firm fixation in concrete structures by expanding their anchoring volume. This type of footing has a wide range of applications and can be used to secure building supports, pipes, fences and other equipment.

Another common type of footing is the bolted footing. They are commonly used to attach structural members, such as steel beams and concrete walls. Bolt-on feet are usually made of metal and have a tapered cone angle that provides greater tensile strength when secured. This type of footing can come in handy where high strength connections are required, such as bridges, foundations and lifting equipment.

In addition to the traditional areas of construction and engineering, footings are also vital in automotive manufacturing and ship construction. In automotive manufacturing, footings are used to connect the engine to the chassis, axles and body structure to ensure the stability and safety of the vehicle. In ship construction, footings are indispensable for connecting vital components such as the hull structure, anchor chains and propellers.

As industrial technology continues to evolve, so do footings, which are constantly being improved and modernized. New high-strength feet can withstand greater loads and pressures while reducing the weight and cost of the structure. Some feet are also corrosion and abrasion resistant, allowing them to be used in harsh environments for long periods of time without being affected. These innovative footing technologies offer more options and possibilities for a variety of industries.

Post time: Aug-19-2024