In the industrial field, casters as an important mobile equipment accessories, its choice is directly related to the equipment’s mobile efficiency, safety and service life. In the face of a wide range of industrial casters on the market, how to buy the right casters has become a challenge for many enterprises and factories. Here are some suggestions on how to buy the right industrial casters.

A clear use of the scene and demand

In the purchase of industrial casters before, first of all, to clarify the use of the scene and demand. Different industrial environments have different requirements for casters, such as ground material, load capacity, frequency of movement and so on. Only clear these needs, in order to target the selection of appropriate casters.

Second, choose the right material

The material of industrial casters directly affects its durability, load-bearing capacity and performance. Common industrial caster materials include nylon, rubber, polyurethane, synthetic rubber, cast iron and so on. Different materials have different characteristics, such as polyurethane wheels wear-resistant, oil-resistant, high and low temperature resistance, nylon wheels lightweight, impact resistance. It is crucial to choose the right material according to the usage environment and demand. Such as supermarkets, schools, hospitals, office buildings, hotels and other places, due to the ground is good, smooth and carry goods lighter, (each caster load in 50-150kg), suitable for the choice of thin steel plate 3-4mm stamping molding electroplating wheel frame, its wheel frame light, flexible operation, quiet and beautiful. This plating wheel frame can be divided into double rows of beads and single rows of beads according to the arrangement of the beads, if often moving and handling, that is, should use double rows of beads; in factories and warehouses, etc., the handling of goods is very frequent and the load is heavier (each caster bearing 150-680kg), it is suitable for the use of a thick steel plate 5-6mm stamping and hot forging and welding of the double-row beads of the wheel frame; if for the handling of heavy loads, such as textile factories, automobile factories, mechanical If it is used to carry heavy loads such as textile factories, automobile factories, machinery factories, etc., due to the heavy loads and long walking distances (each caster carries 700-2500kg), it should be chosen to use the wheel frame with a thick steel plate of 8-12mm cut and welded, and the movable wheel frame uses the flat ball bearings on the base plate, so that the casters can be equipped with the functions of high load-bearing, rotating and flexible, and impact-resistant, etc. at the same time.

Third, choose the appropriate caster bracket

Caster bracket is a key component connecting casters and equipment, and its quality and stability directly affect the use of casters. When choosing caster bracket, consider its carrying capacity, stability, durability and flexibility and other factors. According to the weight of the equipment and the frequency of movement to choose the appropriate caster bracket to ensure the safe movement of the equipment.

Fourth, calculate the load-bearing capacity of casters

In the purchase of industrial casters, it is necessary to calculate the load-bearing capacity of each caster. This needs to be determined according to the self-weight of the equipment, the maximum load and the number of casters used. At the same time, a safety factor has to be taken into account to ensure that the casters will be able to carry enough weight in actual use. In order to be able to calculate the load capacity of various casters, it is necessary to know the dead weight of the transportation equipment, the maximum load and the number of casters used. The load capacity of a caster is calculated as follows: T=(E+Z)/M×N: T=load capacity of a caster; E=self-weight of transportation equipment; Z=maximum load; M=number of casters used; N=safety coefficient (about 1.3-1.5).

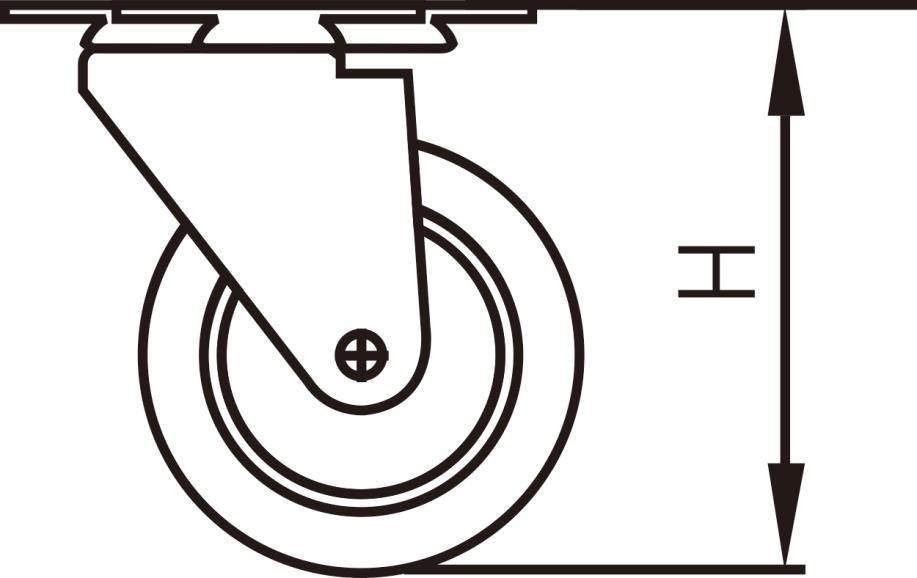

Fifth, choose the right wheel diameter

The size of the wheel diameter directly affects the mobile performance of the equipment and the protection of the ground. Generally speaking, the larger the diameter of the wheel, the easier it is to push and the greater the carrying capacity. However, it is also necessary to choose the appropriate wheel diameter according to the actual needs in order to avoid waste and unnecessary costs.

Six, to ensure that the wheel rotation flexibility

The rotational flexibility of the wheels directly affects the moving efficiency and safety of the equipment. High-quality ball bearings can improve the rotation flexibility of the wheel, reduce resistance and noise. In the purchase of industrial casters, pay attention to the choice of installing ball bearing wheels to ensure its rotational flexibility, lightweight.

Seven, consider the temperature condition of the product

Industrial environments often have extreme temperature conditions such as cold and high temperature. In the purchase of industrial casters, to consider the temperature adaptability of the product. For example, polyurethane wheels can remain soft and flexible at low temperatures, and high-temperature resistant wheels can maintain stable performance at high temperatures.

Eight, routine maintenance and inspection

After selecting the appropriate industrial casters, standardized routine maintenance and inspection is equally important. Regularly check the fastening of the casters, bearing wear and tear and the amount of lubricant, etc., and timely replacement of damaged casters and parts can extend the service life of the casters and keep their performance stable.

In short, the purchase of suitable industrial casters need to consider a number of factors, including the use of the scene, materials, brackets, load capacity, wheel diameter, rotational flexibility and temperature adaptability and so on. Only by comprehensively considering these factors, can we purchase industrial casters that meet the actual needs and improve the efficiency and safety of equipment movement.

Post time: Dec-25-2024