In modern industrial production, mobile equipment and machinery often need to move and stop frequently. In order to ensure safe and efficient operation at the production site, the brake wheel becomes an indispensable component. Its design and working principle directly affect the stopping stability and movement control of the equipment.

1. Mechanical structure

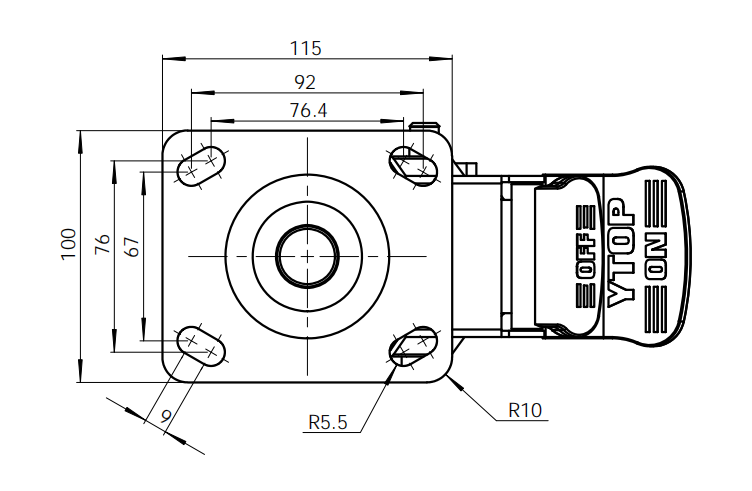

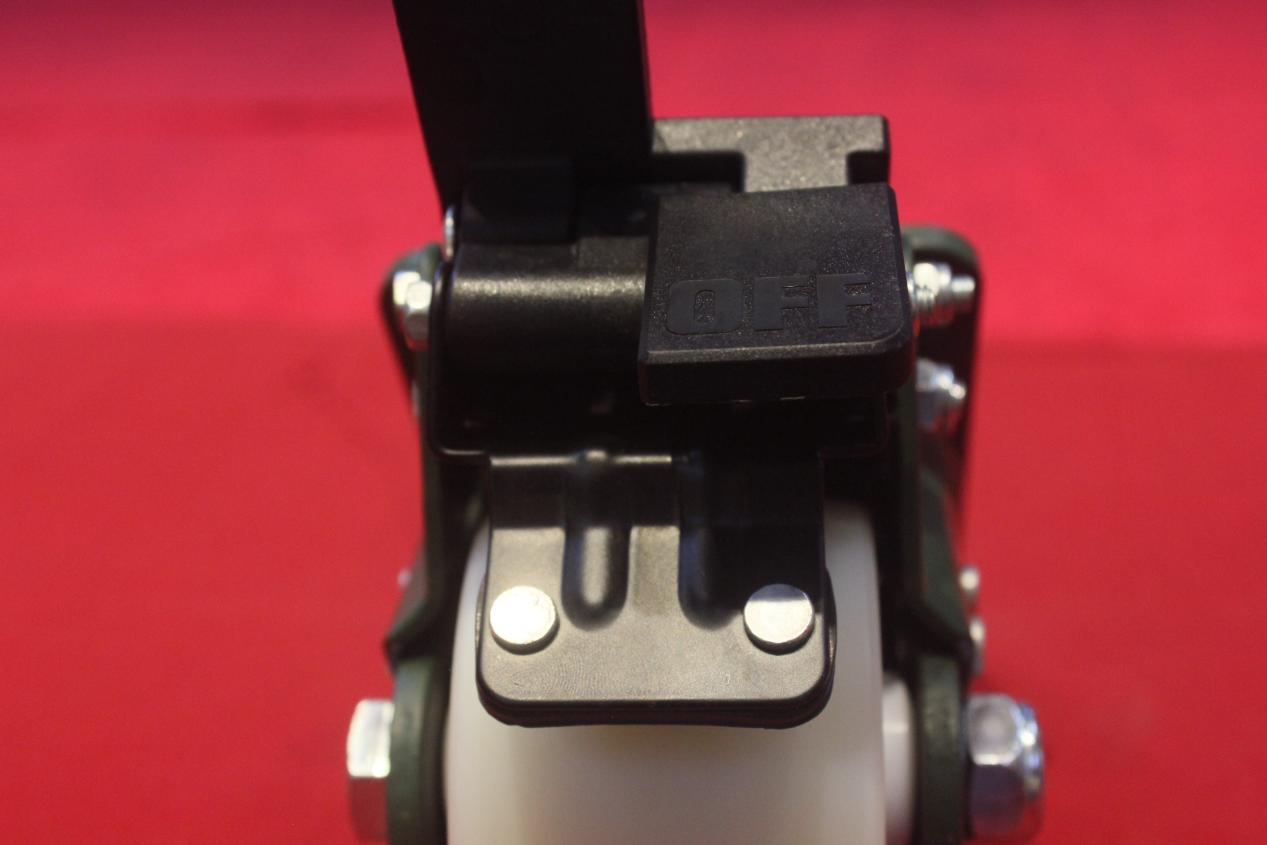

The mechanical structure of industrial caster brake usually includes brake disk, brake pad, caster and brake pedal. When the brake pedal is pressed, the brake pads contact the brake disk through a mechanical transmission system, and braking force is generated. This mechanical structure ensures reliability and stability when the equipment is stopped.

2. Braking force transmission mechanism

The braking force transmission mechanism of industrial caster brakes is usually based on mechanical principles and hydraulic systems. When the brake pedal is pressed, the mechanical transmission system brings the brake pads into contact with the brake discs, which through friction converts the energy of the movement of the equipment into thermal energy, thus stopping it. Hydraulic systems, which are more common in some high-load or large equipment, enhance the braking force through the transfer of fluids and ensure more responsive braking control.

3. Special designs for industrial environments

Industrial caster brakes are often required to cope with a variety of harsh industrial environments, and are therefore designed to be more robust and durable. The selection of wear-resistant materials, dust- and water-resistant designs, and improved corrosion resistance are all aspects of the special design of industrial caster brakes. This guarantees the reliability and durability of the brakes in all types of production sites.

Post time: Jul-08-2024