Casters are an important component of mobile equipment, and an understanding of their structural construction is critical to their performance and application. Casters are usually composed of a bracket and a wheel (single wheel), and the material and design of the bracket and wheel affect the overall performance of the caster. The following is a detailed analysis of the structure of casters from various aspects.

First, caster type

Casters are mainly divided into directional casters and universal casters. Directional casters are equipped with a single wheel on the bracket, and can only move in a straight line on the track; while universal casters can be steered through 360-degree bracket combined with a single wheel, allowing the equipment to move freely in any direction.

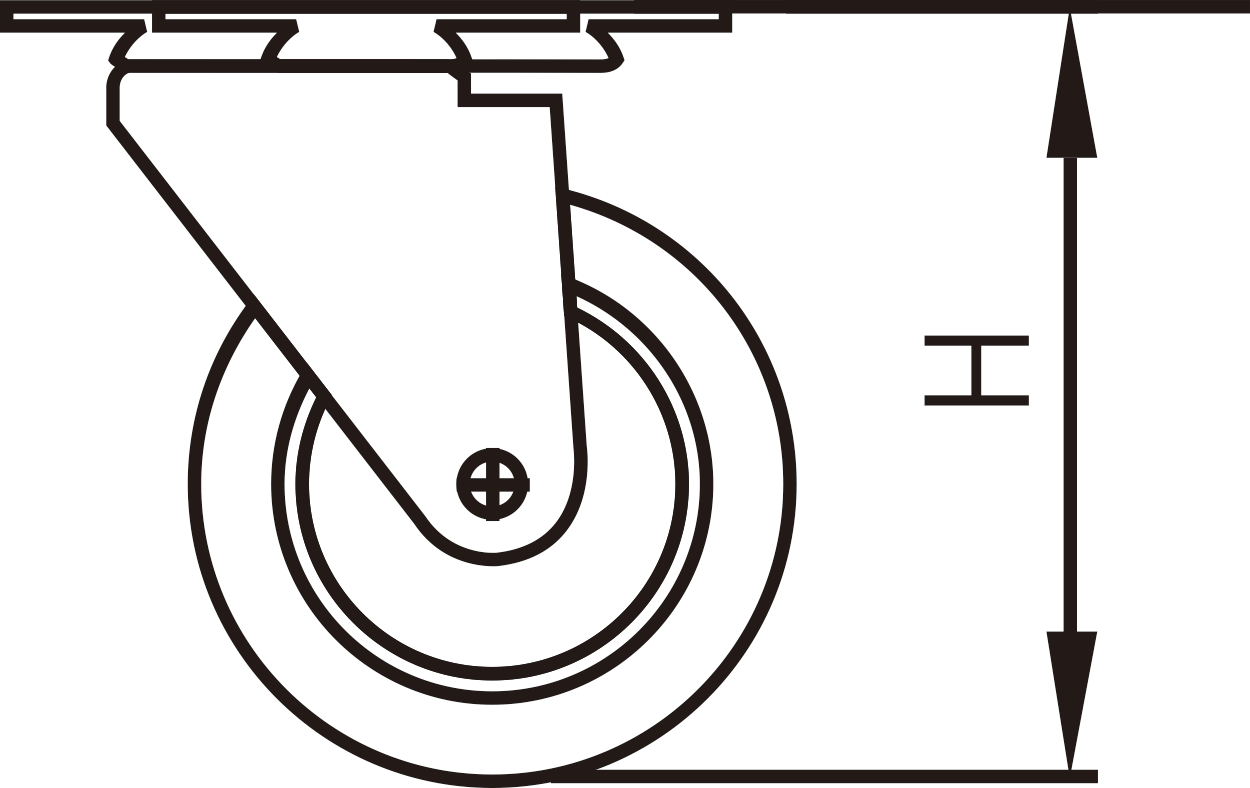

Second, the installation height and bracket steering center distance

The installation height of the caster refers to the vertical distance from the ground to the equipment installation position, specifically expressed as the maximum vertical distance between the caster base plate and the edge of the wheel. Bracket steering center distance refers to the vertical line of the center rivet to the center of the wheel core of the horizontal distance, this distance has a direct impact on the steering performance of the caster.

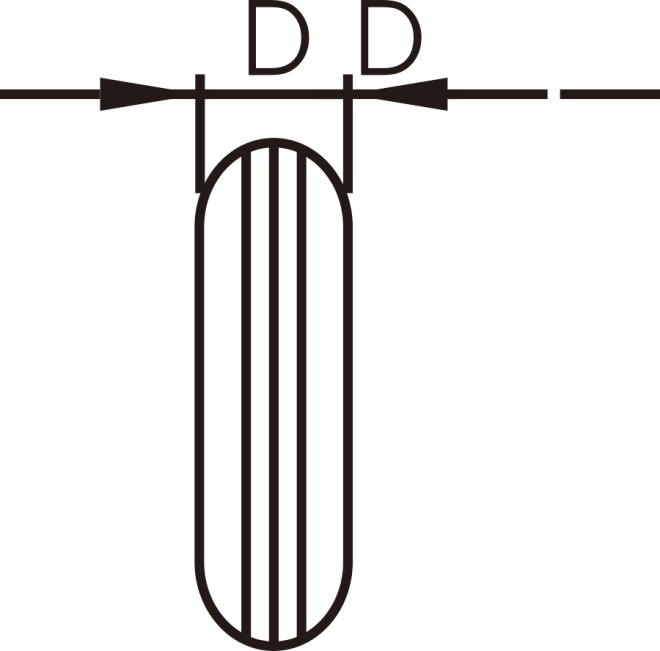

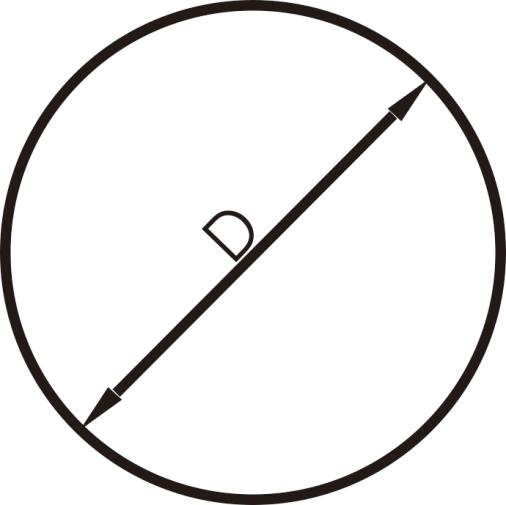

Third, turning radius

Turning radius is a key parameter for assessing the steering performance of casters, which refers to the horizontal distance from the vertical line of the center rivet to the outer edge of the tire. Appropriate turning radius can ensure that the caster can realize smooth 360-degree steering, while unreasonable turning radius may lead to steering difficulties or wheel shaking, which will affect the service life of the caster.

Four, steering performance

The steering performance of casters is affected by factors such as wheel material, width and hardness. Hard, narrow wheels are easier to steer than soft, wide wheels. However, too short a turning radius will make steering more difficult, while too large a radius may cause the wheel to wobble and shorten its life.

Fifth, traveling flexibility

The traveling flexibility of casters is affected by various factors such as bracket structure, steel selection, wheel size, type and bearing. Usually, the bigger the wheel, the better the traveling flexibility. On the smooth ground, hard, narrow wheels compared to the flat side of the soft wheel is more labor-saving; but in the uneven ground, soft wheels can better protect the equipment and play a shock-absorbing role.

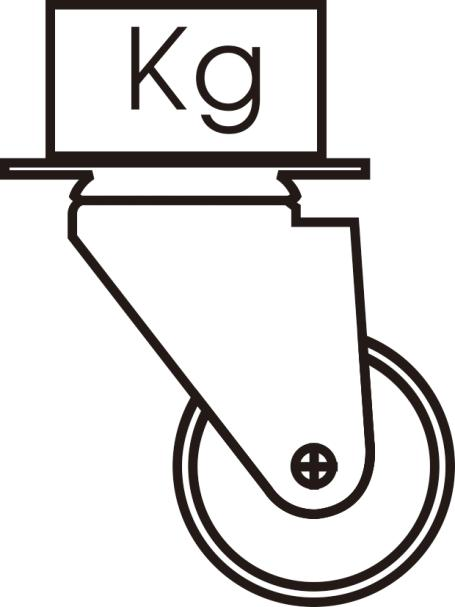

VI. Traveling load (dynamic load)

The dynamic load of a caster is the weight-bearing capacity it can bear when moving. This indicator varies depending on the factory’s testing methods and the material of the wheel. The structure and quality of the support is critical to resist shock and vibration, thus ensuring that the caster remains stable when carrying heavy loads.

VII. Shock Load

When the equipment is subjected to bearer impact or vibration, casters need to have a certain instantaneous load-bearing capacity, that is, impact load. This performance requires casters to maintain stable support and steering ability in sudden situations.

Eight, static load

Static load refers to the weight that the caster can bear in the static state. Generally speaking, the static load should be 5-6 times of the traveling load (dynamic load), and at least 2 times of the impact load. This index ensures that the caster can still maintain stable support performance in a long time under static condition.

In summary, although the structural construction of casters is simple, the details and performance requirements are very complex. Through in-depth knowledge of caster types, mounting heights, turning radii, steering performance, driving flexibility, driving loads, shock loads and static loads, we can better select and utilize casters to ensure that they perform optimally in a variety of application scenarios.

Post time: Oct-12-2024