When it comes to the maintenance of industrial casters, many people may find it a headache because it will always have wear and tear during use. However, wear and tear can also be divided into normal loss and abnormal damage. Wear and tear due to use is a normal phenomenon, but we can likewise reduce this wear and tear through some means, thus extending the use cycle of casters. Therefore, the maintenance of industrial casters is very necessary.

Inspection and maintenance of casters

1. Bearing status check: carefully check whether the wheel bearings are broken, cracked or abnormally worn. If the bearings are found to show signs of damage, stop using them immediately and consider replacing them with new ones.

2. Re-assembly: If the bearing parts are not damaged, but there are loose or unstable conditions, they can be re-assembled. In the process of assembly, make sure all parts are installed correctly and fastened reliably.

3. Assemble anti-tangling cover: If you often encounter the problem of wheels being entangled by debris, it is recommended to assemble anti-tangling cover. This can effectively prevent debris from entering the bearing and reduce the possibility of the wheel being entangled.

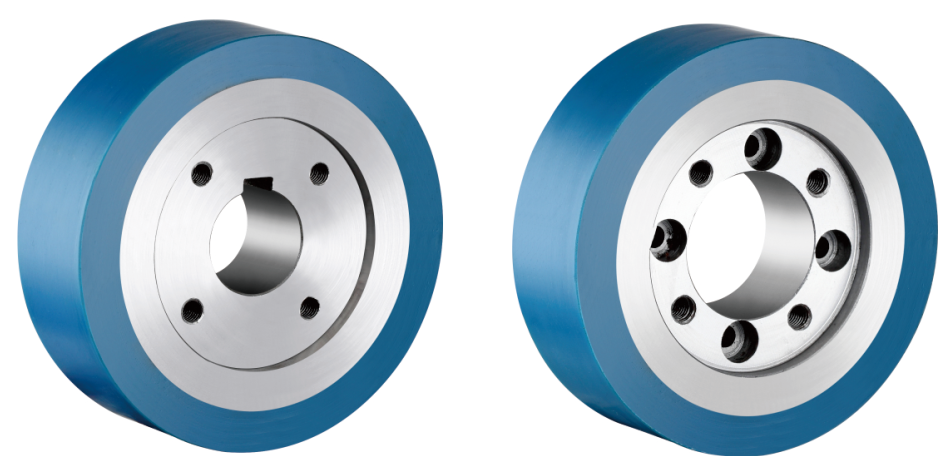

Third, the inspection and replacement of rubber casters

Rubber condition check: Regularly check the condition of rubber casters to ensure that they are in good condition. After a long time of use, rubber casters may be seriously broken, become slack and other problems, these problems will lead to rolling instability, air leakage, abnormal loads and damage to the bottom plate and other consequences

Timely replacement: If you find that the rubber casters are seriously broken or become slack, you should stop using them immediately and replace them with new casters in time. This will avoid downtime and cost loss due to caster damage.

Looseness and jamming check: Universal wheel casters may become loose or jammed during use. These problems can lead to the “grinding point” phenomenon, which affects the rolling performance and rotational flexibility of the equipment. Therefore, it is necessary to regularly check the status of the universal wheel casters to ensure that it is fastened reliably and rotates flexibly.

Bolt tightness check: When checking the universal wheel casters, pay special attention to the tightness of the bolts. If the bolts are loose, they should be tightened in time; if the bolts are damaged, they should be replaced with new ones.

Lubricant check and add: For the universal wheel casters which need lubrication, the amount of lubricant should be checked regularly. If the lubricant is insufficient, it should be added in time; if the lubricant is deteriorated or polluted, it should be replaced with new lubricant.

When inspecting and maintaining casters, special consideration should also be given to the effects of ground conditions. If the ground condition is poor (e.g. uneven, oily, etc.), it can cause additional wear and damage to the casters. Therefore, after using industrial casters, it is important to check the wear and tear according to the ground conditions and deal with them accordingly. If the ground condition is too bad, it is recommended to take other measures (e.g. laying protective mats, using special material casters, etc.) to reduce the wear and damage to the casters.

In summary, regular inspection and maintenance of casters is one of the most important measures to ensure proper operation of mobile equipment. Through the inspection and maintenance methods provided in this guide, the wear and tear of casters can be effectively reduced, their life cycle can be extended, and the operational efficiency and safety of the equipment can be improved.

Post time: Nov-25-2024