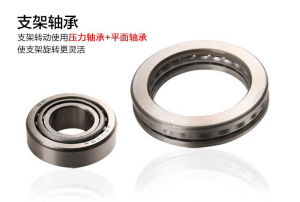

Casters, as an indispensable part of many mechanical equipment and logistics equipment, their stability and durability directly affect the overall performance and service life of the equipment. As the core component of casters, the quality of caster bearings and the correctness of their installation are crucial. This article will discuss in detail the correct installation method of caster bearings to ensure the normal use of casters and extend their service life.

First of all, we need to clarify the importance of caster bearings in the production process. Different manufacturers may have differences in the selection and installation methods of bearings when producing casters. But no matter what method is used, the quality of the product should be guaranteed as a prerequisite. Inferior bearing products will not only affect the use of casters, but also may cause damage to the equipment, or even cause safety accidents. Therefore, choosing reliable quality bearings and adopting correct installation methods are the keys to ensure the stable performance of casters.

Next, we will detail the steps and methods of installing caster bearings:

一、Pre-installation

1. Cleaning bearings and components: Before installation, bearings and their related components should be cleaned to remove oil, dust and other impurities to ensure that the installation environment is clean.

2. Check the dimensions and finishing of the components: check the dimensions and accuracy of the bearings and related components to ensure that they meet the installation requirements.

二、Installation steps

1. Installation: According to the structure and fit of the bearings, appropriate installation methods are used. For cylindrical bore bearings, press-in or hot mounting methods can be used; for tapered bore bearings, they can be loaded directly on the tapered shaft or loaded using a sleeve.

2. Post-installation inspection: After the installation is completed, the bearings should be inspected to ensure that they are correctly installed and free from looseness. At the same time, check whether the rotation of the bearing is flexible and smooth.

3. Supply lubricant: according to the use requirements of the bearings, select the appropriate lubricant to add. The selection of lubricant should take into account the working environment of the bearing, temperature and other factors to ensure the normal operation of the bearing.

三、Precautions

1. In the installation process, the workshop operation process specification should be strictly adhered to, so as to avoid damage to the bearings or unsound installation due to improper operation.

2. The mounting method of the bearings should be selected according to the structure of the bearings, the way of coordination and other factors to avoid blind operation.

3. Before installation, the bearings and related parts should be cleaned and inspected to ensure that the installation environment is clean and the parts are intact.

4. In the installation process, attention should be paid to the protection of bearings and anti-rust measures to avoid rust or damage to bearings due to improper storage.

In conclusion, the correct installation of caster bearings has an important impact on the performance and service life of casters. By choosing suitable bearings and adopting correct installation methods and precautions, the stability and durability of casters can be ensured, and the efficiency and safety of equipment can be improved.

Post time: Feb-26-2025